2020-08-26

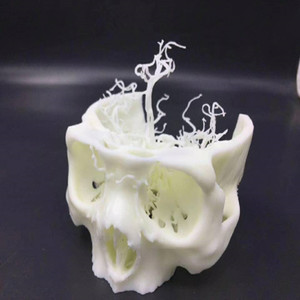

This is a 3D printing technology widely used to create different types of models, patterns and prototypes. I will discuss the prototype later in this article. SLA rapid prototyping stands for stereolithography technology and is also known by different names, such as stereolithography equipment, optical manufacturing, photocuring or resin printing. In order to produce detailed drawings of parts, the technology uses photopolymerization, a process that uses light to link molecular chains to form a polymer. In the past few years, a lot of research has been carried out on this technology. Today, it has been widely used in the production of metal plates, CNC processing, metal manufacturing, etc. Because this efficient technology greatly reduces time, it is used to build and test electric vehicles.

Stereolithography is an additive manufacturing process in which ultraviolet light is focused on a large tank filled with photosensitive polymer resin. CAD (Computer Aided Design) technology is used to draw designs or shapes on the surface of the photosensitive polymer tank by ultraviolet light. Photosensitive polymers are sensitive to ultraviolet light. As the light falls on them, they begin to solidify, so they become the desired 3D objects.

SLA must provide many advantages. The most important one is speed. Compared with other methods on the market, it has the ability to create the required 3D objects in a shorter time. Using this technology, functional parts can be manufactured in one day. Not only that, this technology allows easy processing of 3D printed prototypes and designs, and can also be used to create master models for injection molding, thermoforming, blow molding, and various other casting methods.

Although it can produce almost any synthetic design, the price may be slightly higher, and the cost is as high as 250,000 US dollars compared with the cost of ordinary photopolymers of about 800 US dollars.

In the past few years, several types of research have been conducted. As a result, Ilios Photon and Form 2 appeared, which greatly reduced the cost of SLA printing. SLA can help quickly create 3D models or patterns, while rapid prototyping is used to manufacture or assemble scale models of physical parts using 3D computer-aided design data.

Changsha’s Tianxin District Celebrates Lantern Festival with Four-City Historic Tower Light Linkage

Xun County, C China's Henan: Young Artisans in "Hometown of Stone Carving" Bring Millennium-Old Craft to Life

Inside MWC 2026: See How China Mobile Leads the Tech Innovation Wave

China Eastern Airlines Announces Comprehensive Upgrade to International Route Network in 2026

SOUEAST S08 DM Pre-sale Opens in the UAE:"Motorsuite" Redefines Quality Travel

iCAUR Makes Strategic Entry into the Middle East: Announcing V27's Global Launch in UAE

©copyright2009-2020Fresh life