2022-09-21

The pressure oil of the variable piston pump enters the lower cavity of the variable casing through the pump body and the oil passage hole in the variable casing of the pump housing through the one-way valve. When the tie rod moves downward, it pushes the servo piston to move downward and the upper valve port of the servo valve opens, the pressure oil in the lower cavity of the variable casing enters the upper cavity of the variable casing through the oil passage hole in the variable piston, and because the upper cavity area is larger than the lower cavity, the hydraulic pressure pushes the piston to move downward and drives the pin to make the variable head rotate around the The piston is pushed downward by the hydraulic pressure, which drives the pin to rotate the variable head around the center of the steel ball, changing the tilt angle of the variable head (increasing), and the flow of the piston pump increases. Conversely, the lever moves upward, the tilt angle of the variable head changes in the opposite direction, and the flow rate of the pump changes. When the tilt angle changes to zero, the variable head changes to the negative declination direction, the liquid flow is reversed, and the inlet and outlet of the pump is changed. Due to the high pressure, compact structure, high efficiency and convenient flow adjustment of the piston pump, it is widely used in systems requiring high pressure, large flow, high power and occasions where the flow needs to be adjusted, such as gantry planer, broaching machine, hydraulic machine, engineering machinery, mining and metallurgical machinery, and ships.

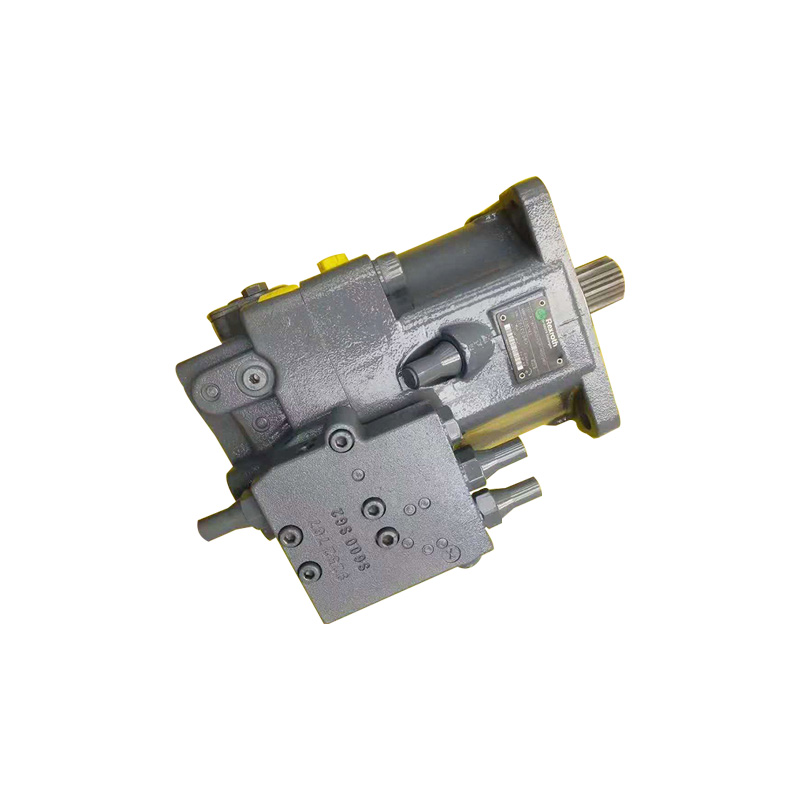

According to the arrangement of the plunger and the direction of movement, can be divided into radial piston pump and axial piston pump two categories, according to the type of flow distribution device can be divided into with gap seal type flow distribution vice piston pump and valve flow distribution device piston pump two categories, according to the displacement is variable into quantitative piston pump and variable piston pump.

With high pressure resistance, high efficiency, high transmission power, wide speed range, long life, the disadvantage is the harsh requirements for the cleanliness of the working medium, complex structure and high price, maintenance difficulties, etc..

Plunger pump is a hydraulic pump that relies on the plunger in the cylinder for reciprocating motion to cause changes in the sealing volume to achieve suction and pressure, compared with gear pumps and vane pumps, this pump has many advantages.

First of all, the parts that constitute the sealing volume are cylindrical plunger and cylinder bore, easy to process, can get high precision, good sealing performance, still have high volumetric efficiency in high pressure work.

Second, only need to change the working stroke of the plunger to change the flow, easy to achieve variable.

Third, the main parts in the plunger pump are subject to compressive stress, the material strength performance can be fully utilized. -The swash plate structure axial piston variable pump is used for hydraulic transmission in open circuit hydraulic system.

-Mainly used in the field of engineering travel machinery.

-Pumps operate under self-priming conditions, tank pressurization or with built-in booster pump (centrifugal pump).

-A variety of control options are available to meet the requirements of various applications and to meet different operating requirements.

-The power control can be adjusted externally even when the pump is running.

The pump has a through-shaft drive and is suitable for joining gear pumps and axial piston pumps (100% through-uranium drive).

-The output flow is proportional to the drive speed and can be varied steplessly between maximum and zero values.

Zhejiang Zhanpeng Hydraulic Technology Co., Ltd. is a modern enterprise integrating R&D, production, sales and maintenance. The company has many machining centers, high-precision CNC lathes, high-precision grinding machines, automatic three-dimensional coordinate instruments, digital hydraulic test benches and other

production and testing equipment. We have professional and high quality technical team, strict production management system and perfect testing means.

The company mainly produces hydraulic piston pumps, hydraulic motors, hydraulic valves, etc., and can also provide users with hydraulic system (components) testing, maintenance, commissioning, selection, design optimization services. It is a professional, large-scale and diversified hydraulic components manufacturer in China. Our products are widely used in many fields such as mining machinery, metallurgical machinery, engineering machinery, agricultural machinery, marine machinery, etc.

Quality first, integrity for the soul" is the Zhanpeng people's unchanging patriarch, we will provide you with excellent products and quality service, welcome customers at home and abroad to visit us.

Cheng Laifeng

392963649@qq.com

Cruise passengers stranded in Dubai and Strait of Hormuz warzones

Trump launches military action in another country days after attacking Iran

US Secretary of War says Iran 'tried to assassinate Donald Trump'

Monkey 'tied with rope around neck' in live 'execution' performance

First UK evacuation flight from the Middle East 'takes off' for London

Container vessel hit by Iranian missile forcing crew to abandon ship

©copyright2009-2020Fresh life